Enhance Your Space This Spring with Top Flooring Trends from Danek Flooring Inc.

April 25, 2024

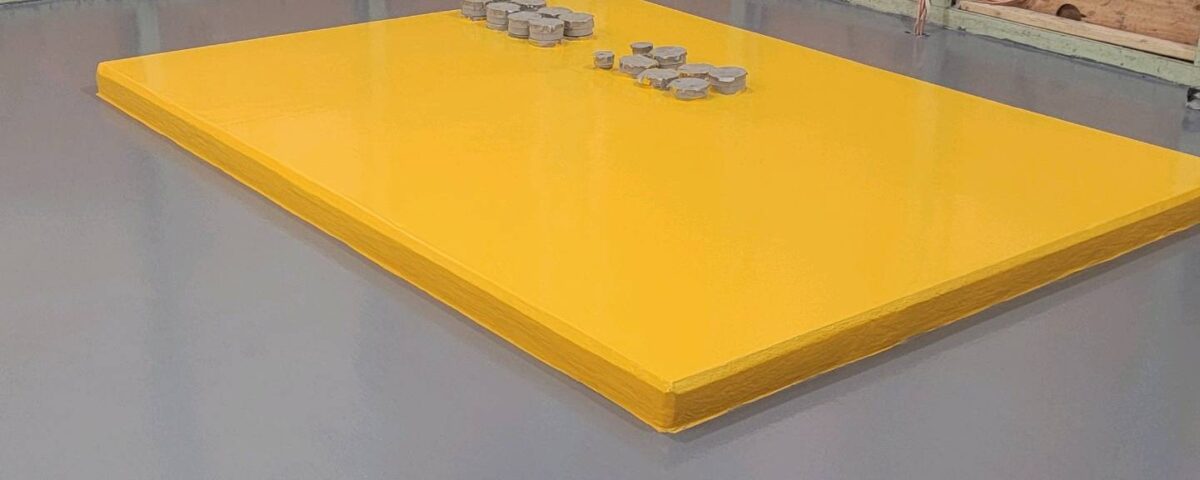

Commercial Epoxy Flooring Installation for High-Traffic Interior Space

January 20, 2026Commercial Epoxy Flooring with Concrete Repair

Danek Flooring completed a commercial epoxy flooring installation that included

structural concrete removal, reinforcement, and patch repair before applying a

high-performance epoxy flooring system. This project required precise coordination

between demolition, concrete repair, and resinous flooring installation to ensure long-term durability.

Need epoxy flooring over damaged concrete?

Danek Flooring specializes in slab repair,

moisture mitigation, and

commercial epoxy systems.

Call Danek Flooring: (413) 645-5100

Project Overview

- Project Type: Commercial Epoxy Flooring

- Facility Use: Utility / Industrial Space

- Region: Massachusetts

- Flooring System: Moisture-Blocking Epoxy with Slip-Resistant Grout Coat

Concrete Removal & Reinforcement

Portions of the existing concrete slab were removed to address deterioration and integrate new structural support.

This type of work is common on aging industrial slabs and is a core part of our

commercial concrete repair services.

The exposed area was reinforced using steel rebar to restore slab integrity and prepare the surface for repair.

Concrete Repair Scope Included

- Saw cutting and selective concrete removal

- Cleaning and preparation of exposed substrate

- Installation of steel reinforcement

- Concrete patch and leveling

Surface Preparation for Epoxy Flooring

After concrete repairs were completed and cured, the entire floor area was mechanically prepared using

dust-free, vacuum-assisted diamond grinding equipment.

Proper surface preparation is critical for epoxy adhesion and long-term performance and is standard across all

commercial floor preparation services.

Preparation Steps

- Mechanical grinding including edgework

- Cleaning and vacuuming of the slab

- Minor crack and divot repair

- Vertical surface preparation up to 4 inches

Moisture-Blocking Epoxy System Installation

The specified flooring system included a pigmented moisture-blocking epoxy primer

followed by a pigmented epoxy grout coat with slip resistance.

This system was designed to handle moisture vapor transmission while providing a durable, easy-to-clean surface.

Epoxy System Installation Steps

- Apply moisture-blocking epoxy primer

- Allow proper cure time

- Sweep, detail, and tape adjacent areas

- Apply pigmented epoxy grout coat with slip resistance

- Final cure and seal

Cure Time: Floors were allowed to cure for 24–72 hours at an average temperature

of 68°F before returning the space to service.

Slip Resistance & Safety Considerations

Slip resistance was incorporated into the epoxy grout coat to improve traction in active work areas.

This is especially important in utility and industrial environments and aligns with our

industrial flooring safety standards.

Commercial Epoxy Flooring Contractor in New England

Danek Flooring installs epoxy flooring systems for commercial and industrial facilities throughout

New England. Our approach focuses on

proper slab repair, moisture control, and system selection to deliver long-lasting flooring solutions.

Request pricing for commercial epoxy flooring

Learn more about our commercial epoxy flooring services

or tell us about your slab condition, facility type, and project timeline.

Call: (413) 645-5100

FAQ: Epoxy Flooring with Concrete Repair

Can epoxy flooring be installed over repaired concrete?

Yes. When repairs are properly reinforced, patched, and mechanically prepared, epoxy systems can be installed

successfully over repaired concrete slabs. Learn more about our

concrete repair process.

Why is moisture-blocking epoxy important?

Moisture vapor transmission can cause coating failure. A

moisture-blocking epoxy primer

helps protect the system and improve long-term performance.

Is slip resistance recommended for epoxy floors?

Yes. Slip-resistant additives are strongly recommended in commercial and industrial environments for safety.